Production Procedure

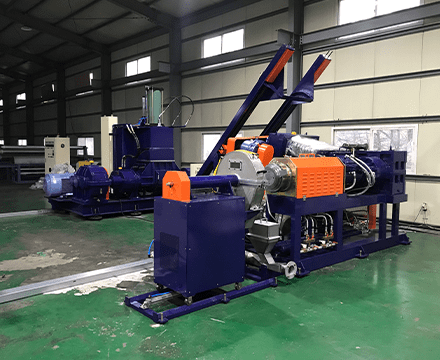

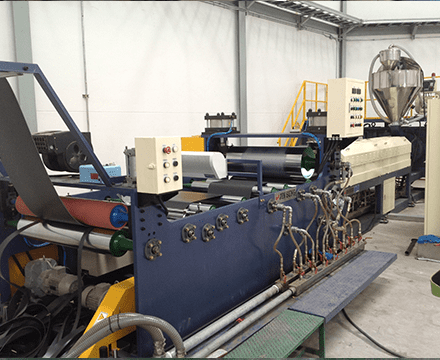

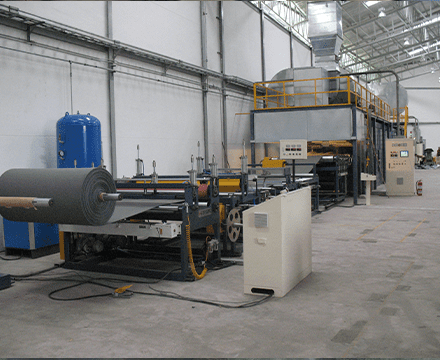

Chemically Cross-linked PE Foam Sheet is produced in an eco-friendly way from the procedure consisting

of a kneading & compounding, mother sheet extrusion and cross-linking & blowing.

Kneading & Compounding

-

Materials Kneading

-

Materials Compounding & Pelletizing

-

Pellet Drying / Stabilizing

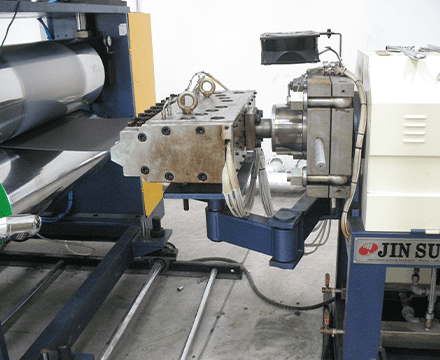

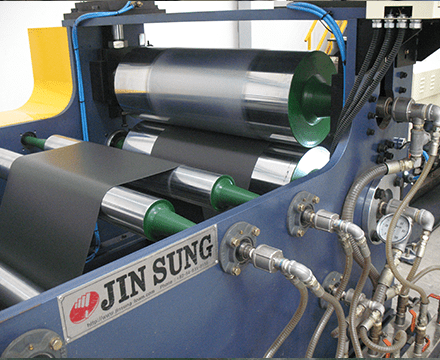

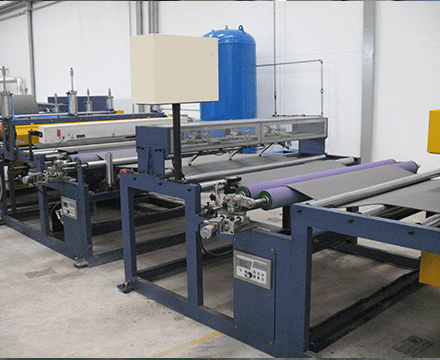

Mother Sheet Extrusion

-

Mother sheet extrusion

-

Forming & sizing

-

Winding / Stabilizing

Cross-linking & Blowing

-

Cross-linking

-

Blowing

-

- Cross-linked foam sheet Cooling

- Cross-linked foam sheet Winding in Roll

Properties

- Excellent insulation materials (cold-warm)-Applicable between -40℃ to +115℃

- Excellent ventilation and stepping and knocking sound insulation.

- Resistant to vapours, chemicals, and acids.

- Fire resistance grade offers good fire resisting property

- Insects and rodents will not eat it. Thin, flexible , UV resistant.

-

Superior Processibility : Can be cut by scissors or knife, Easy to Laminate, Can be glued to each other or to metals,

Weldable (by hot air blower hand welder), Easy Vacuum-formable - Easy to do-it -yourself.

- Environment-friendly product, No health hazard.

Applications

If you cannot see the text, click on the area and scroll left and right.

| Construction | Insulation | Automobile | Sports & Leisure | Miscellaneous |

|---|---|---|---|---|

| Concrete pavement joint |

Hot or cold Pipe line thermal insulation |

Auto Roof Top Liners | Gymnastic Wall | Carpet Underlay |

| Edge strip | Sound insulation |

Watershield / Auto Noise Barrier |

Body Protection (shin, elbow, knee and shoulder) |

Swimming Boards & Water Toys |

| Roof insulation/td> | Air Duct insulation | Sun Visor | Underfloor sound insulation | Mats For Camping, Trekking |

| Slip membrane | Corrugated Roof insulation | Motor Undershield | Fielder's Shin Guards | Soft Luggage |

| Building foundation | Tunnel insulation | Boot Liners | Shoe Lining |

Double-coated Foam SupportedTape |

| Gasket | Head Gear | |||

| Air Conditioning | Gymnastic Mat | |||

| Door Trim |

Specifications

If you cannot see the text, click on the area and scroll left and right.

| Model No. | Size of Extruder’s Screw | Capacity of Extruder | Thicknesse | Width | Density |

|---|---|---|---|---|---|

| JS-XPE 150 | 150 mm | Max. 150 kg/hr | 3~15 mm | 600~1500 mm | 23~184 kg/㎥ |

| JS-XPE 170 | 170 mm | Max. 200 kg/hr | 3~15 mm | 2,200 mm | 23~184 kg/㎥ |