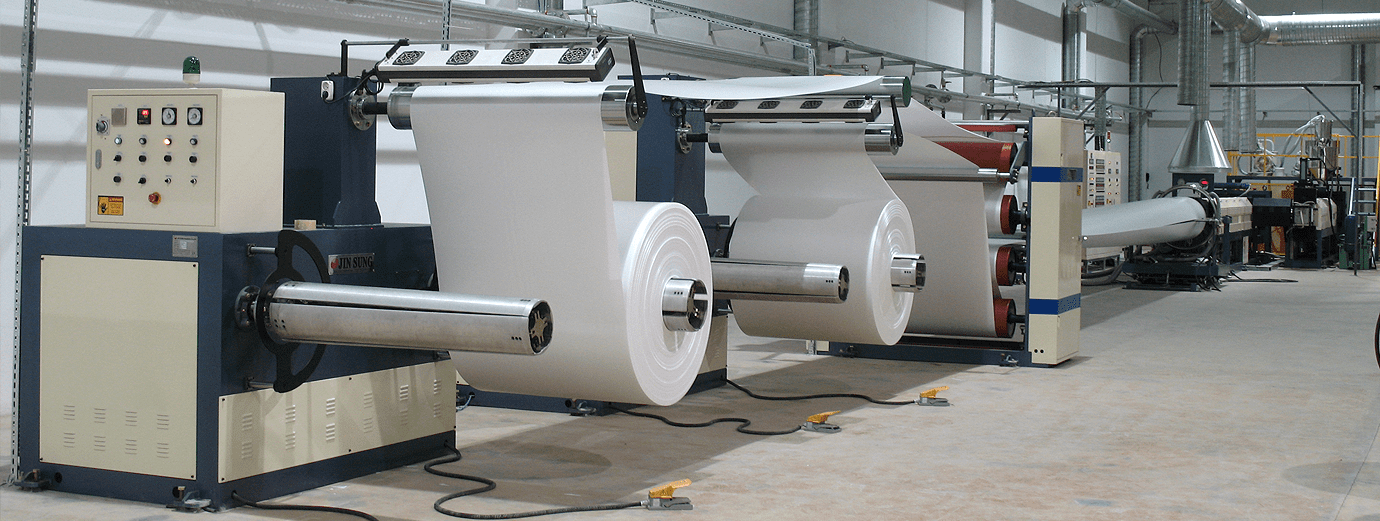

PS Foam Sheet Extrusion Line

PS Foam Sheet Extrusion Line uses a tandem extruder technology to produce fine-blocked cell-structured extruded Polystyrene foam sheet with

high strength and a pearly and even surface, in a continuous roll, from Polystyrene injecting an eco-friendly blowing gas and additives.

Features

High Quality & Superior Output

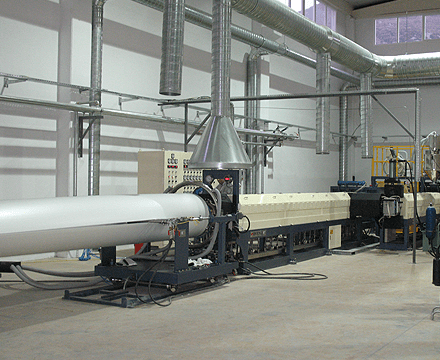

- JIN SUNG Machinery’s Tandem Extruder, an integral component of the PS Foam Sheet Extrusion Line, consisting of a primary extruder

which melts and intensively mixes Polystyrene with a blowing gas and other additives and a secondary extruder optimizes cooling and

forwards the melt to the forming die enabling proper and maximum output. - JIN SUNG Machinery’s unique Screw provides intensively mixing enabling the production of quality foam sheet with

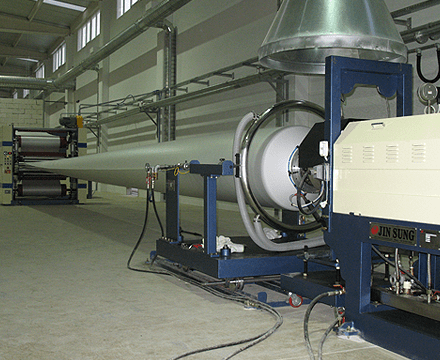

virtually any cell size, density, flexibility and surface texture. - JIN SUNG Machinery’s Dies are engineered to high tolerances to specified process requirements as the other integral component of the

PS Foam Sheet Extrusion Line, provides efficient processing and the flexibility to create the highest quality foam sheet to meet

today's diversities of market demands.

-

EXTRUDER

-

MANDRUL TO TAKE UP UNIT

-

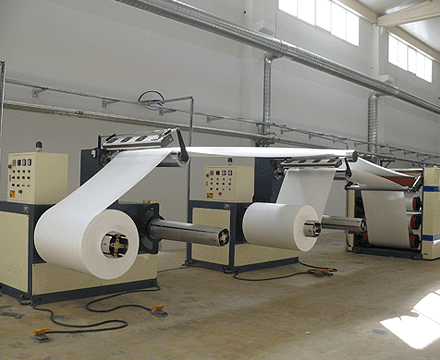

WINDER UNIT

Applications

- PS foam board undergone second expansion via multi-layer bonding for Acoustic and Thermal insulation like wallpaper,

carpet under-layer and sun roof board in the construction field to save huge of energy.

- Due to its characteristic of easy vacuum thermal formability, PS foam sheet can be vacuum formed for disposable food containers like Tray

of fruits, vegetables and fish, fast food take-out boxes, lunch box, egg box, bowls, table-wares and other various types of food containers. - PS foam sheet can be laminated with film or paper for Education materials, decorating objects, advertising board.

- printable, foldable, embossable, moisture and water resistant, low steam and air permeability, micro-resistant, excellent insulating properties.

Specifications

If you cannot see the text, click on the area and scroll left and right.

| Model | JS-PS 100-130 |

JS-PS 120-150 |

JJS-PS 130-170 |

|---|---|---|---|

| Width(mm) | 600-1300 | 600-1300 | 600-1300 |

| Thickness(mm) | 0.8-6 | 1.4-6.5 | 2-7 |

| Screw Dia.(mm) | 100 & 130 | 120 & 150 | 130 & 170 |

| Capacity(kg/hr) | 150-200 | 200-300 | 200-350 |